Few industries are as competitive as manufacturing. With high overhead, long supply chains, and fierce international competition, success in manufacturing often comes down to how well one can play the margins. After decades of decline, North American manufacturing is coming to life again due in no small part to innovations that have made it possible for companies to reduce labour costs through automation and use their competitive edge to improve service and drive down prices.

Technological improvements have been a key factor in this. Production lines are more integrated than they have ever been before, and one of the most exciting areas of development has been the ever-more sophisticated network being built between quality control and actual production, which has made it possible to drastically reduce waste and improve efficiency.

Coordinate Measuring Machines (CMMs) have played an important role in this. CMMs have long been an important factor in making sure products and parts meet blueprint specifications, and because they offer a much greater degree of accuracy than would be possible using hand measurement tools, they play an important role in catching small errors before they become big errors.

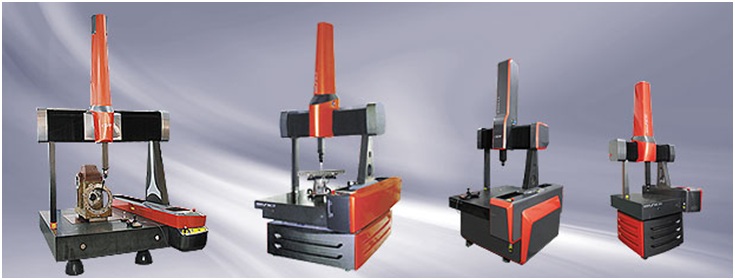

Here is a brief guide to some of the most popular CMMs on the market, and the particular uses to which they are most suited. If you are looking for a CMM for your business, remember that the best prices on CMM equipment are available from specialized metrology solutions providers, who can advise you on the best CMM for your applications, and provide you with the most appropriate software.

Bridge CMM

Since the 1970s, Bridge CMMs have been the mainstay of coordinate metrology. Offering precision and reliability at a cost-effective price point, bridge CMMs can be found in a wide range of different industries. Bridge CMMs are the most common coordinate measuring machines on the market, and can handle most small to medium sized parts.

Gantry CMM

Gantry CMMs operate much like Bridge CMMs but on a significantly larger scale. They tend to be used in the automotive and aerospace industries, where whole parts can be quite large, but where extreme accuracy is still vitally important.

Vision And Multisensor Systems

Most CMMs use a tactile probe in measuring parts and products, but when it comes to extremely small parts, or extremely delicate ones, a probe can be an ineffective measuring tool. In cases such as these, non-tactile measurement solutions are necessary. Video scanners and white light scanners all provide alternative measurement solutions that combine a high degree of accuracy with a contactless approach that can measure any components over 600 mm sq. in area and 200 mm tall.

Portable CMMs

The most well known portable CMM device is probably the ROMER Arm, which is accurate, rugged, and ideal for situations where you need to be able to move the CMM around a part or product to capture its dimensions from all sides.

Each of these CMMs is ideal for a particular application, and finding out which one can improve efficiency and quality on your production line will depend on your particular needs. But one thing is sure: competition in manufacturing is only going to become more intense in the coming years. By equipping your production line with the best possible CMM, you are ensuring that you will be up to the challenge of an evolving market.

![Watch Video Now on xiaohongshu.com [以色列Elevatione perfectio X美容仪 perfectio X 全新仪器黑科技了解下]](https://www.techburgeon.com/wp-content/uploads/2019/07/perfectiox-singapore-150x150.jpg)